Sticky Roller

Industrial standard sticky roller is a common used cleaning products found in PCB, LCD or LED process. The adhesive level on the roller will use to remove lint, dust or particle sitting on the flat surface device.

Industrial standard sticky roller is a common used cleaning products found in PCB, LCD or LED process. The adhesive level on the roller will use to remove lint, dust or particle sitting on the flat surface device.

Maxway Tec has works with qualified sticky roller manufacturer in order to supply quality sticky roller for clean room and relevant industry. We have 2 major type of sticky rollers for most application.

Choices of Sticky Roller

- PP – Traditional Manual Cutting Type

- PP – Knife Free Type

General Introduction of Sticky Roller

The sticky roller is made from PP material attach on environmental friendly synthetic substrate releasing layer. We are using acrylic solvent base adhesive to form a stable adhesive layer without adhesive transfer during the lint and particle removal process.

Our sticky roller is able to maintain a consistent thickness and flatness in order to achieve a stable contact with the PCB, LCD and LED product surface.

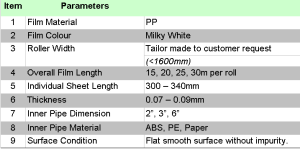

General Physical Properties of Sticky Roller

Sticky Roller Properties

Introduce Knife-Free Type Sticky Roller

Knife-free type sticky roller is our improved version from traditional manual cutting roller. The PP layer could be easily tearing off with bare hand. This will be effectively reduce machine down time and not require sharp knife within the process. The cutting edge is seamless joint with each sticky sheet without causing any surface protrusion.

Many industries with high requirement had adopted the knife-free type sticky roller in their process. Please call Maxway Tec to learn more about this type of knife-free sticky roller.