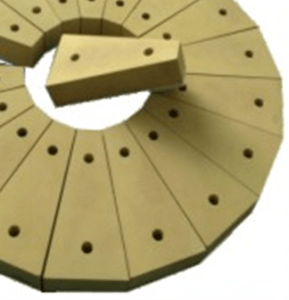

Lapping stone also name as PVA lapping stone because PVA is used as the binding and porous resin during the lapping stone forming process. PVA lapping stone is a hard and porous grinding stone widely used in surface grinding process. There are also elastic lapping stone available in Maxway Tec product list.

The PVA base lapping stone is the product manufacture from the combination of anti-resistance PVA resin and high removal abrasive. The PVA resin will generate high porous nature in the lapping stone. The porous nature will help the lapping or grinding slug to be flushed by the grinding coolant.

The PVA lapping stone is a common grinding stone used in many grinding tools, it also suitable for metal, aluminum or copper base alloy surface polishing. We can use lapping stone in auto-lapping process such as single or double side CMP process.

Lapping Stone Features

The high porosity nature makes the lapping stone act like a sponge which retains sufficient lapping solution or grinding coolant. The flow of grinding coolant will flush away the lapping slug and maintain a cleaner lapping stone surface. This is the reason the lapping stone we are producing is able to maintain a stable removal rate through out longer period of working time.

The lapping solution also reduces the lapping stone surface temperature in order to ensure no over-heat symptoms happen. The lapping stone over heat will cause the stone hardening which lead to the main reason for surface scratch.

Lapping Stone Application

Lapping is a common process for substance requires high surface quality and performance. We are seeing many PVA lapping stone used in single or double-side lapping process.

Hard disc drive substrate or aluminum spacer which requires high parallelism and surface quality are using lapping stone or grinding stone for achieving the substrate requirement.

With appropriate lapping stone selection, user can achieve smooth surface parameters, such as roughness (Ra) can achieve 60A (angstrom) or even lower.

Lapping Stone Variety

There are mainly 2 types of abrasive materials for lapping stone, namely Green Carbide and Carbide abrasive. Both are having their own market with interchangeable factor.

Besides, we also provide wide variety of abrasive size from mesh 120# up to 3000#. User can choose the appropriate abrasive size for achieving lapping process requirement.

Maxway Tec is supplying or tailor-made wide variety of lapping stone and grinding stone base on individual customer needs. We know there are many companies are scarifying their process yield or capability because unable to obtain a suitable lapping stone. We want to contribute our knowledge with the lapping process or grinding process owner in order to get a suitable lapping stone.

Feel free to contact Maxway Tec and learn more about our grinding stone and lapping stone products.