- Home

- Lapping Stone

- Cleanroom Products

- Seiconductor Test Probe

- Industrial Brushes

- About Maxwaytec Engineering

- Sitemap

- Passive Components

- Diamond Dresser

- Diamond Coated Tools

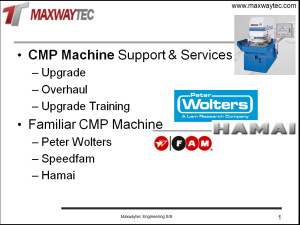

- CMP Machine Overhaul & Services

- Engineering Products

- Engineering Services

- PVA Sponge Roller

- Download

- Twist Wire Brush

- Tools

- Sanding Sponge

- Sitemap

- Polarize Film for LCD Panel

- How to Order Polarize Film

- Wrapping Wire

- Commit to Responsible Business Alliance Code of Conduct

- CMP Process Materials

- 3-ply Health Care Face Mask

- Business Operation Protocol (COVID-19)

- Contact Maxwaytec Engineering

-

How to Determine a Quality Sanding Sponge

- Posted onadmin

- in Sanding Sponge

- onSeptember 5, 2015

- No Comments.

Sanding sponge is a new product launched in the market, since we develop and launched this product, we start seeing new seller coming out similar product in the market. We receive call or email asking us about our sand sponge product quality.

It is never been easy to launch a new product like sand sponge in the market. 3M sanding sponge sometime ago with high price margin, and Maxwaytec Engineering want to bring this product with broader application. Maxwaytec Engineering has spent a substantial amount and effort in sand sponge development process. We are very glad seeing more marketers and manufacturers get involved in these sanding sponge products, at least to show us many people buy the concept. We are very certain about our product quality and we would like to share with you some simple guideline while you are looking for sanding sponge.

Sand Sponge Abrasive

Maxwaytec Engineering has identified quality aluminum oxide as the abrasive used in sand sponge. This aluminum oxide has segregated into 3 difference grid size. The abrasive should be properly segregated to ensure the surface smoothness after the polish process.

- Coarse abrasive. A mesh 30 considers as coarse abrasive. This coarse abrasive sanding sponge is best used for wood surface polishing and removal.

- Medium size abrasive. Mesh 50-100 consider as medium scale abrasive.

- Fine abrasive. Mesh 100, 120 consider a fine abrasive. We recommend this fine abrasive sponge to be used in ordinary household surface polishing or stain removal.

Resin Used in Sanding Sponge

Resin is one of the main composition for determine sanding sponge quality. Many unapproved resin was selected and used in the purpose of cost selection. However a quality resin should fulfill the below requirement:

- Environmental friendly and user friendly.

- Able to hold the abrasive prevent over drop-off during normal application.

Removal efficiency for Sanding Sponge

There are several criteria we could consider while choosing the sand sponge:

- Abrasive size. Select an appropriate abrasive size to get maximum removal rate.

- Surface smoothness or roughness. Always use coarse grain size before using fine grain size abrasive.

- Polish in Wet Condition. Try to polish the surface at wet condition instead of try polish. One of the major advantageous for sand sponge is able to work under wet condition. There are several strong point why we recommend to work under wet condition:

- Less powder removal flying around.

- Surface smoother than dry polish.

- Reduce sludge conglomerate in between the abrasive.

Maxwaytec Engeineering has been participated in surface removal and surface cleaning for industry application. Sand sponge is one of our latest innovations to introduce our knowledge into both industrial and household application. Feel free to contact Maxwaytec to understand more about our sand sponge product. Perhaps, we could even tailor made appropriate sand sponge for your application.

If you enjoyed this article please consider sharing it!

Contact Maxwaytec Engineering

No. 28, 1st Floor Persiaran Mahsuri 1/2,

Sunway Tunas,

11900 Bayan Lepas,

Penang,

Malaysia

Contact:

Mr. Lim CC

Tel #: 0164221975

Email: cclim@maxwaytec.com

Maxwaytec Products & Services

Products

- PVA Sponge Roller

- Lapping Stone

- Diamond Dresser

- Water Filter

- Mohair & Nylon Brush

Engineering Services

- Tooling Design

- Gear Design

- Movement Design

- Mold design

Know more about Maxwaytec Eng.

Contact Maxway Tec

About Maxway Tec

Term & Condition

Sitemap

Disclaimer

Copyright 2014 Maxwaytec Engineering S/B